APPLICATIONS

The

B&P fining station has been designed for use with food

processing technology. To ensure efficiency, stability and suitable

organoleptic properties of their products, manufacturers of

concentrates and beverages use fining agents which must be

precisely dosed during the production processes.

OPERATION

PRINCIPLE

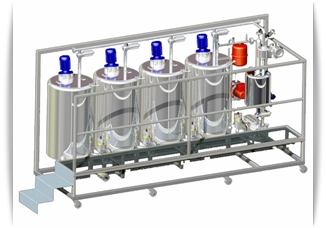

In

its standard version, the B&P fining station is fitted with

four tanks. Two tanks are used for preparing the bentonite solution

while the third tank is used for preparing a colloidal mixture. The

fourth tank is reserved for diluting and heating up gelatine

solutions, and is fitted with its own circulating pump, a heat

exchanger and a water heating jacket. The tank volumes can be

matched to individual customer needs.

A

fully automatic PLC control system has been developed for the

B&P fining station. All fining operations are completely

visualised and can be controlled and monitored via a touch

screen.

In order to perform a fining

operation, you only have to specify the fining substance, its

quantity, the water quantity to be added and the process tank. This

data is used to prepare the solution, which is then directed to the

desired tank. Next, the collector line is rinsed and the system

shuts down automatically. All data is archived according to the

current production monitoring requirements (in particular, with the

HACCP system).

ADVANTAGES

•

High flexibility and efficiency

• Convenient

maintenance

• Fully automatic PLC control system

with visualisation technology

• Low space

requirements

• Time saving

• No losses

• Exact metering

TECHNICAL

DATA

Efficiency Adjusted to the line

size

Control system Simatic

S-7

Power input 5-15 kW

Dimensions Length: 3,540 mm, width:

1,240 mm,

height: 1,876 mm

Steam consumption Max. up to 50

kg/h

Steam pressure 1-4 bar

Material Stainless steel AISI

304/option 316L

SCOPE OF

DELIVERY

• 3

fining tanks, volume: approx. 500 l, with sight glass and fine

scale

• Thermos vessel, approx. 300

l

• 4 stirring units

• JAD pipe heat exchanger with

adjustment system or electrical heat-up

• Circulating pump, delivery rate:

up to 5 m3/h

• SIEMENS SIMATIC S-7 control

cabinet

• Piping between the fining station and the supply

collector

• Baseframe with adjustable feet

OPTIONS

• Touch screen – visualization of the line element working

with the fining station

•

Bentonite vessel with stirring unit and operator’s platform,

volume: 3 m3, material: AISI 304/316L